CATEGORIES

Optic Set-Up

Vertical Emitters

A quick Look from the Side

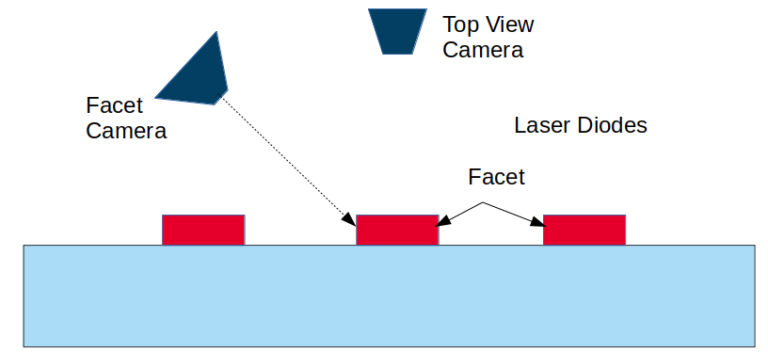

This special optical set-up makes possible to take pictures from the facets without .

When highest resolution is mandatory

If the edge emitter laser has high optical power, long life requirements or both, it almost always means that high-resolution pictures of the facet are mandatory for its visual inspection. For an image with adequate resolution that covers the whole facet and not just a portion, the oblique optic set-up is not sufficient.

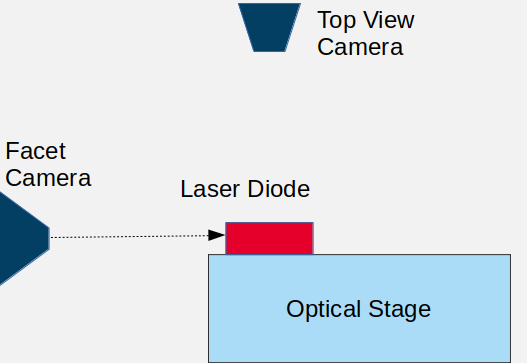

In this case the optic set up require that the camera lense and the facet are perfectly aligned. Some systems hold the device with a robot arm in front of the camera lens but they are more susceptible to bad resolution due to vibrations than systems that actually place the diode on a stage.

Due to the amount of pixels on the CCD chip as well as the camera telescope optics, the whole device facet often cannot be covered by one field of view of the camera. Hence, the reconstruction of an entire

device image from several image sequences is required.

The OptoSystem tool picks up the laser bar and takes the necessary amount of pictures from all sides, even from the bottom. After the classification of the pictures by the algorithm, the bar is either returned to the original container, placed in a new container, or scrapped depending on the specific customization. The pictures can be saved on an HDD for later analysis as well. The optical inspection can be realized as a stand-alone machine (VVSP4000) or integrated into another machine such as an unstacker (VKSV3000) or a tester.

To increase the signal to noise ratio for the classification algorithm not only the camera resolution and its focus but also the illumination are essential factors. The engineers of OptoSystem take pride in the perfect setup of all these necessary conditions and make it very accessible and easy to self-adjust for future optimizations after delivery.

High resolution images are feasible with a dedicated optical stage on which the laser bar rests. After all pictures of one facet have been taken, the stage is rotated 180° and the facet on the opposite side is visually inspected.

Throughput

The optical inspection tool from OptoSystem with dedicated optical stage is best for high resolution pictures. It also provides flexibility since the optical stage is not vulnerable to tool vibrations caused by other moving parts.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.