CATEGORIES

Spectrum

Spectrometer

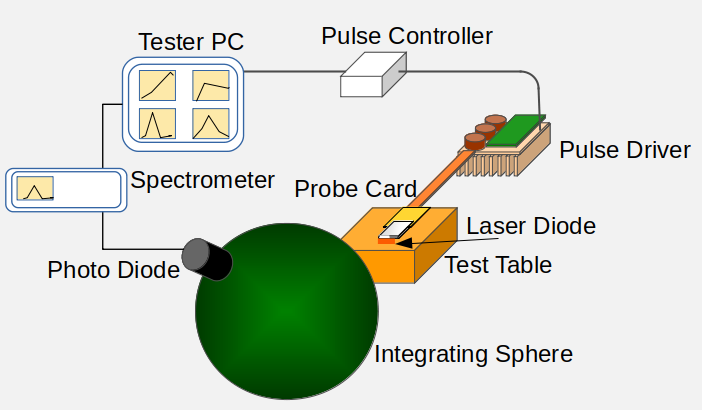

The optical fiber can collect the radiation directly from the integrating sphere or from a dedicated lense that is placed in front of the laser diode. In the spectrometer the light is optically spread at different angles depending on the wavelength. An array of sensors produce the spectrum of the measured light.

Wavelength Parameters

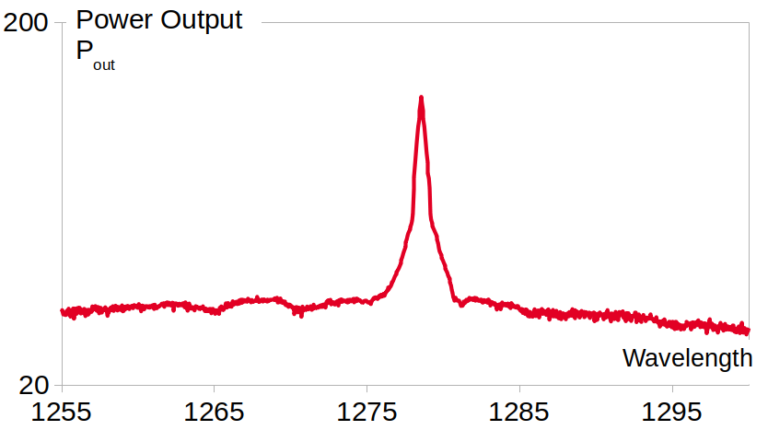

The result of the measurement is a plot of light intensity as a function of wavelength. The numerical parameters that are extracted are usually the center wavelength (also called lasing mode), the mode spacing and the side mode suppression. These parameters are best shown on an actual laser spectrum. A parameter that hardly can be determined by this kind of measurement is the laser linewidth. What can be seen in the spectrometer is most certainly limited by the resolution of the spectrometer itself. Considering a very good spectrometer having a resolution limit in the range of 0.01nm and most laser diodes having a linewidth of 10-3nm or even 10-6nm makes the point clear.

A change in temperature also has an influence on the spectral properties of the laser. Increasing temperature usually leads to increasing laser wavelength. In standard Fabry Perot lasers this shift is related to the change in the refractive index of the laser material with temperature, hence increasing the optical length of the cavity. This material dependent coefficient is often depicted in the datasheets for the different materials such as GaAs, InP and GaN.

For lasers with a distributed feedback structure to select the wavelength, the effect of temperature is more complex and needs to be discussed in relation to the specifics of the distribution grating design.

Do you like what you see?

We value your feedback, so let us know what you think!

Let us also know which topics you would like to see expanded.

Just give us a call, send us an e-mail or use the form to contact us.